PROCESSING

All processes and safety you need,

in one place.

We offer a wide range of professional services and processes to meet the needs of each customer.

We work hard to always ensure that our clients are completely satisfied with the end product.

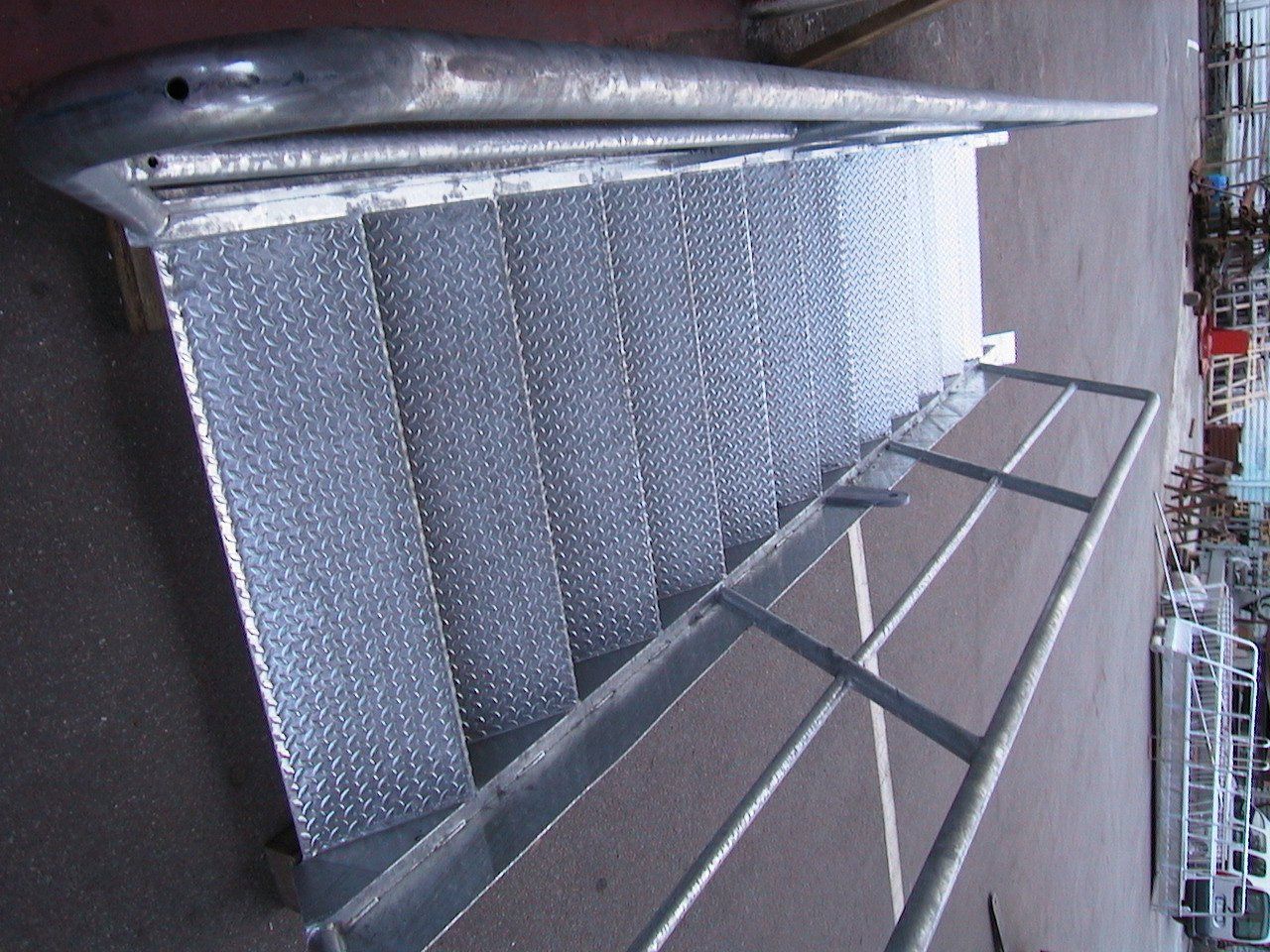

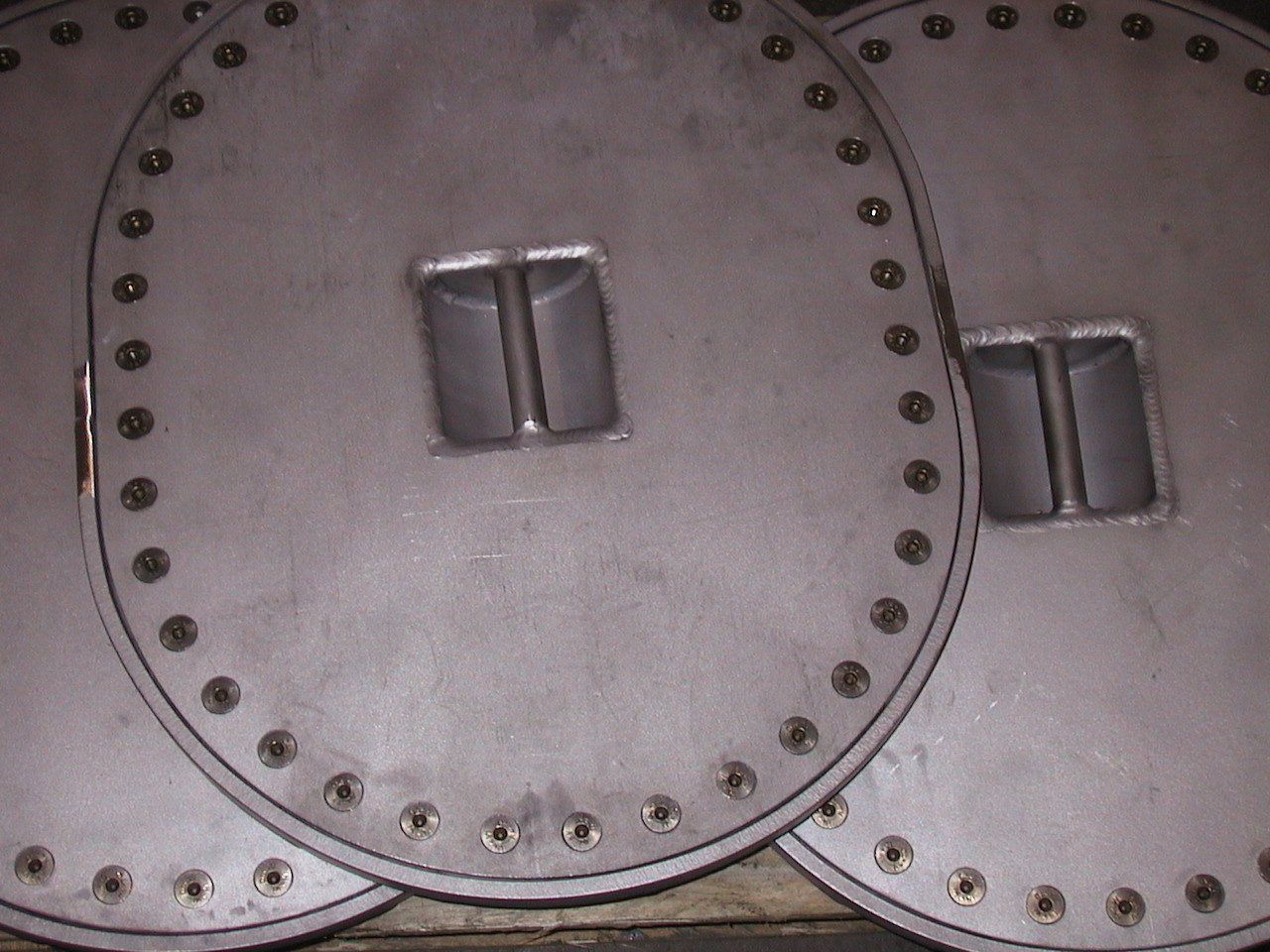

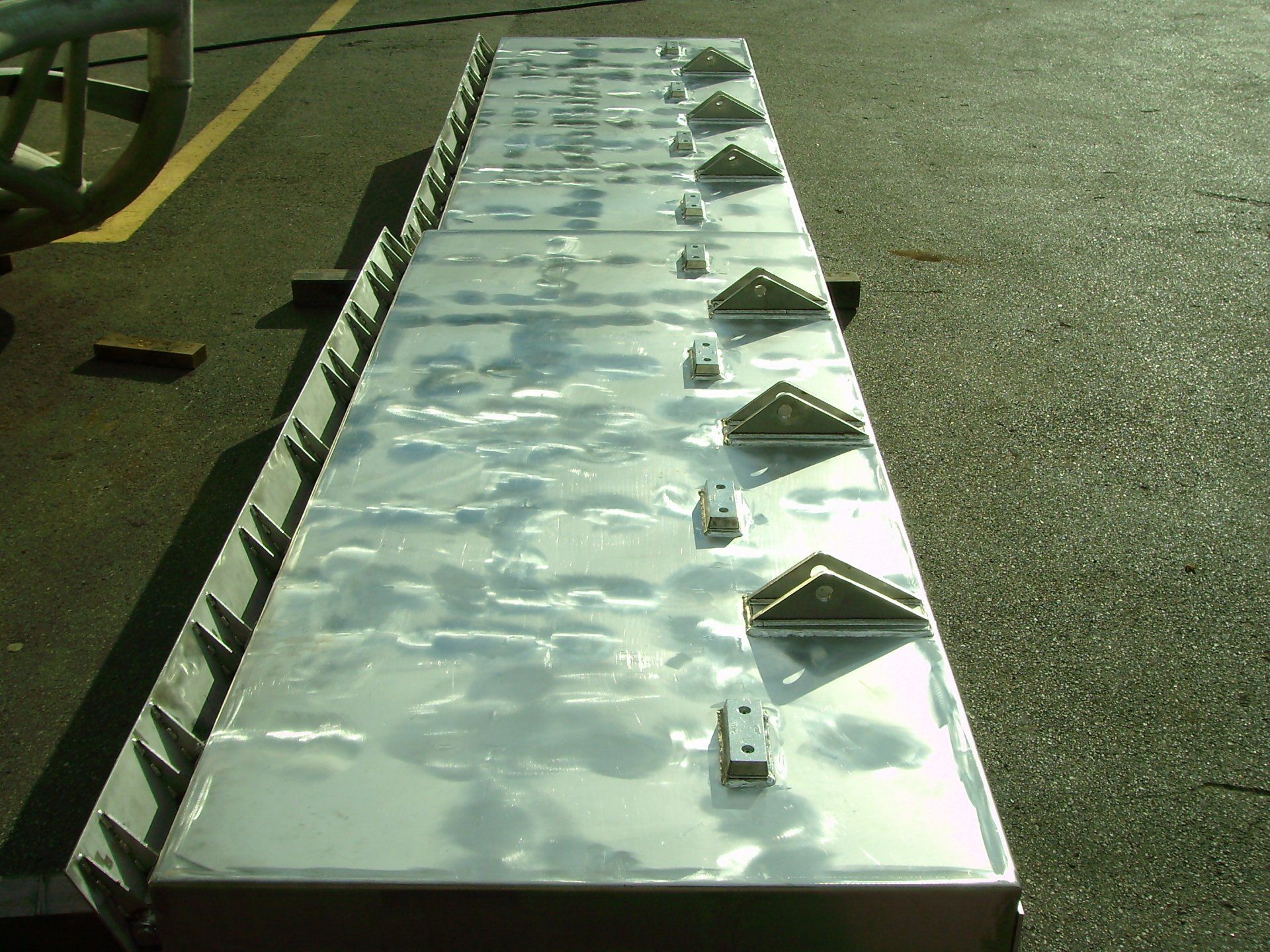

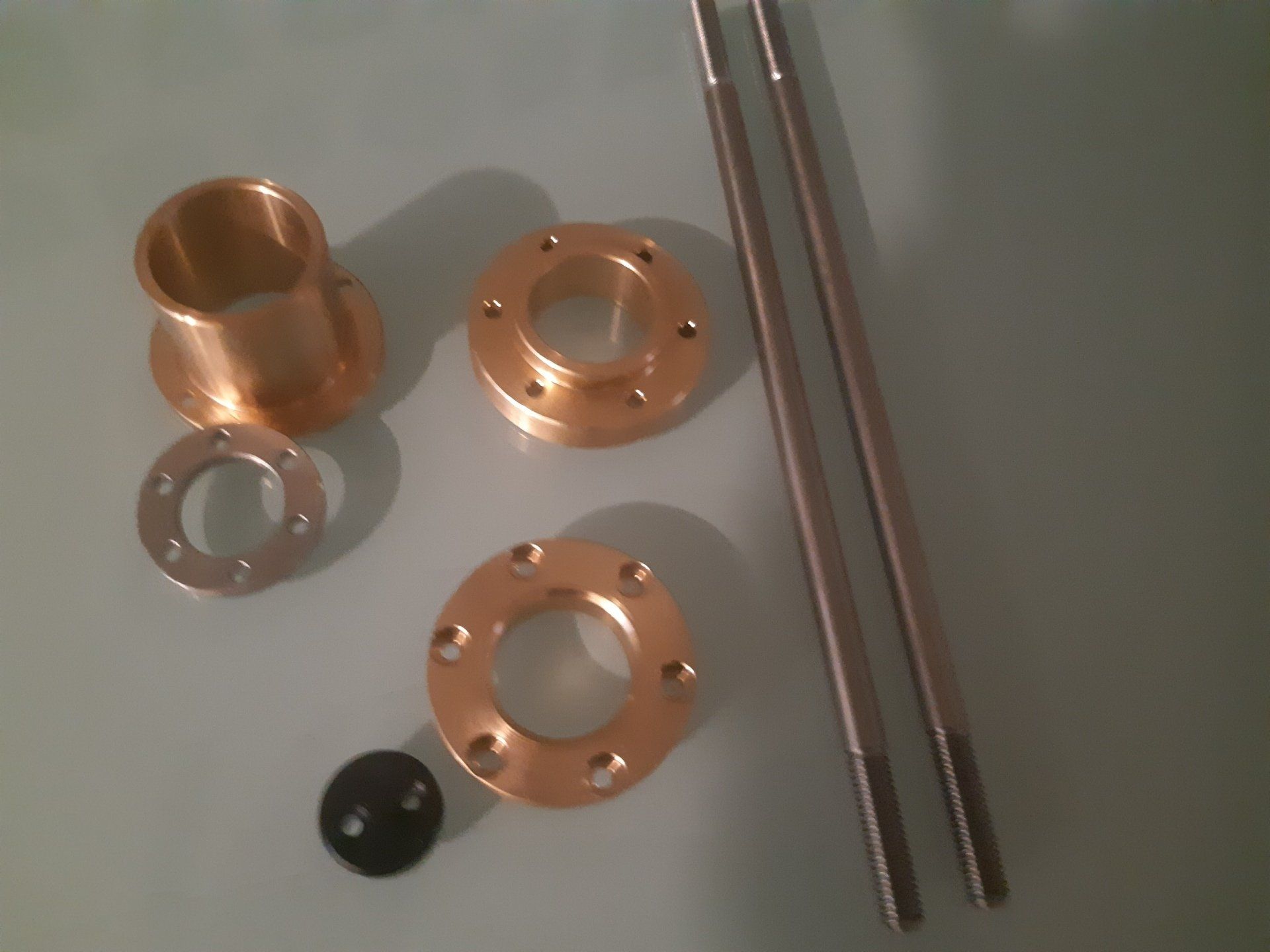

We manufacture custom-made parts in aluminium alloy, carbon steel and stainless steel with extreme accuracy and punctuality.

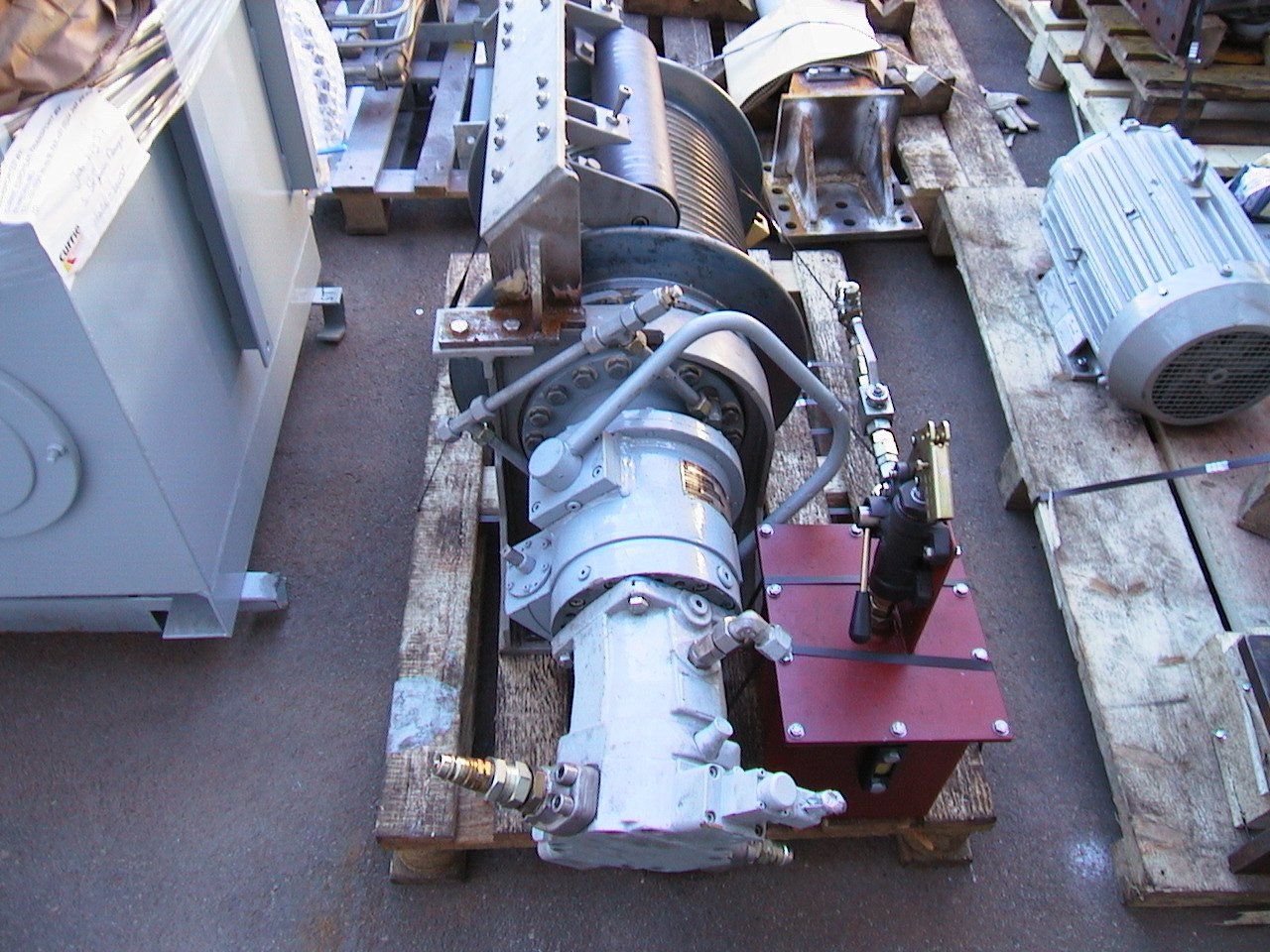

We manufacture and repair naval hydraulic and oleodynamic plants and structural hull elements.

Our R.I.Na. qualified personnel perform:

TIG – MIG – Pulsed MIG – MAG – ARCO welding on Carbon Steel, Stainless Steel, Aluminium Alloys and Copper Alloys.

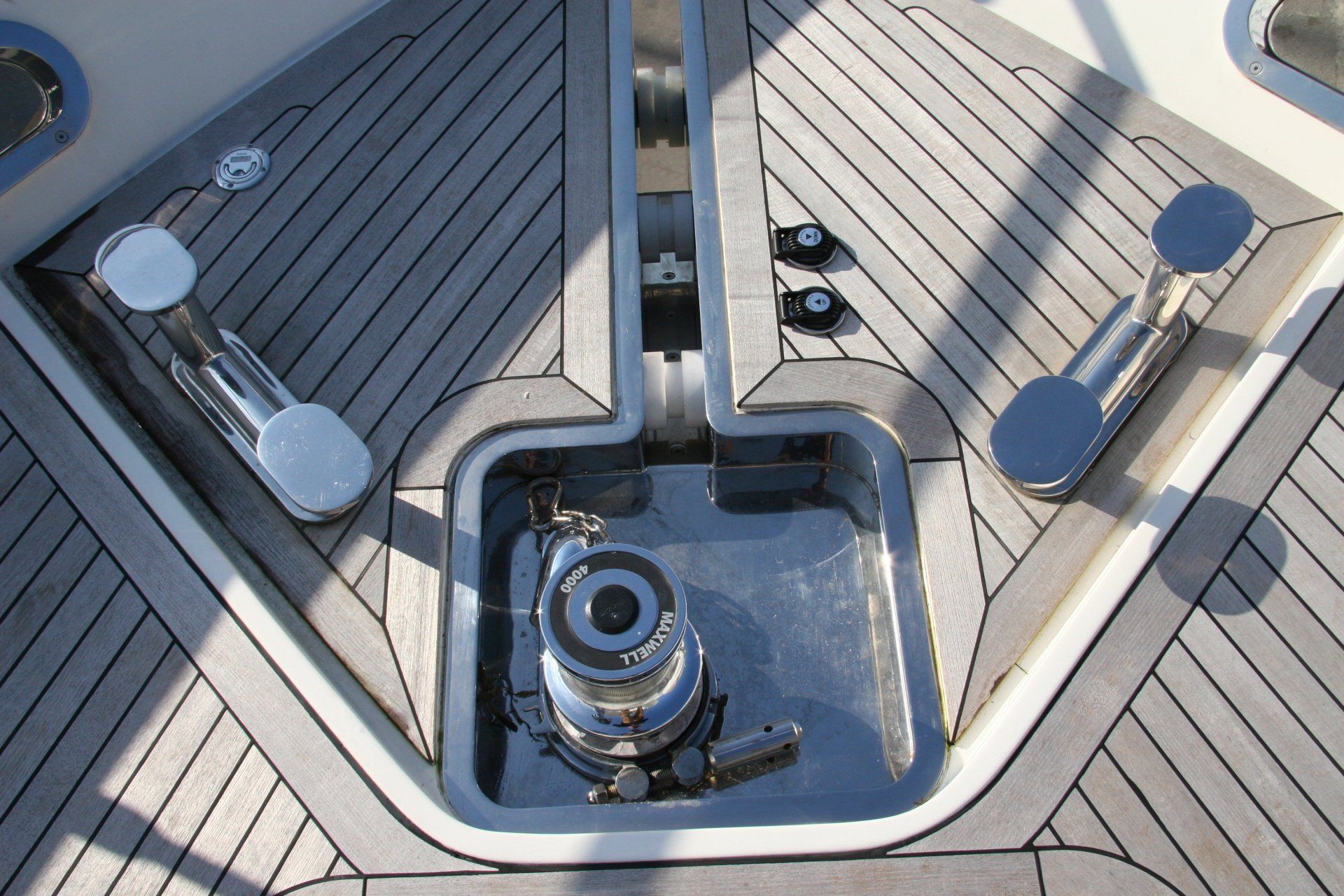

The experience gained over the years working for the most prestigious shipyards allows us to guarantee accurate and precise working processes. Production of mechanical and small parts for any sail system in STEEL AISI 316/ 17-4 ph or aluminum with polishing treatment in the case of stainless steel or anodizing in the case of aluminium. We also build naval furniture fittings such as lamps, knobs, handrails and other accessories.

During a refitting we are able to restore or recreate on-board parts and equipment that respect the original fittings of that boat.

We use specific techniques and processes that restore the original charm of the seafaring art.

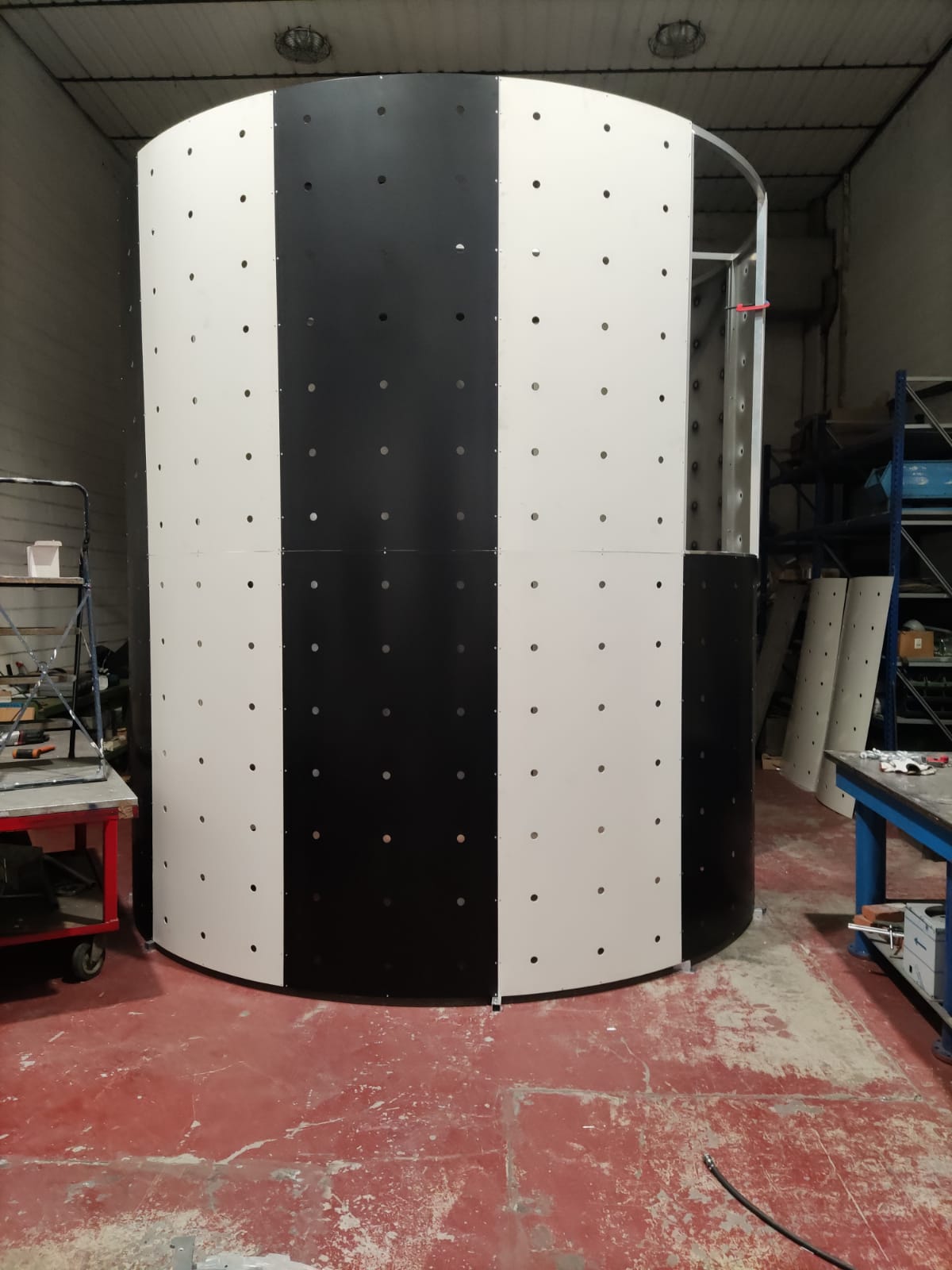

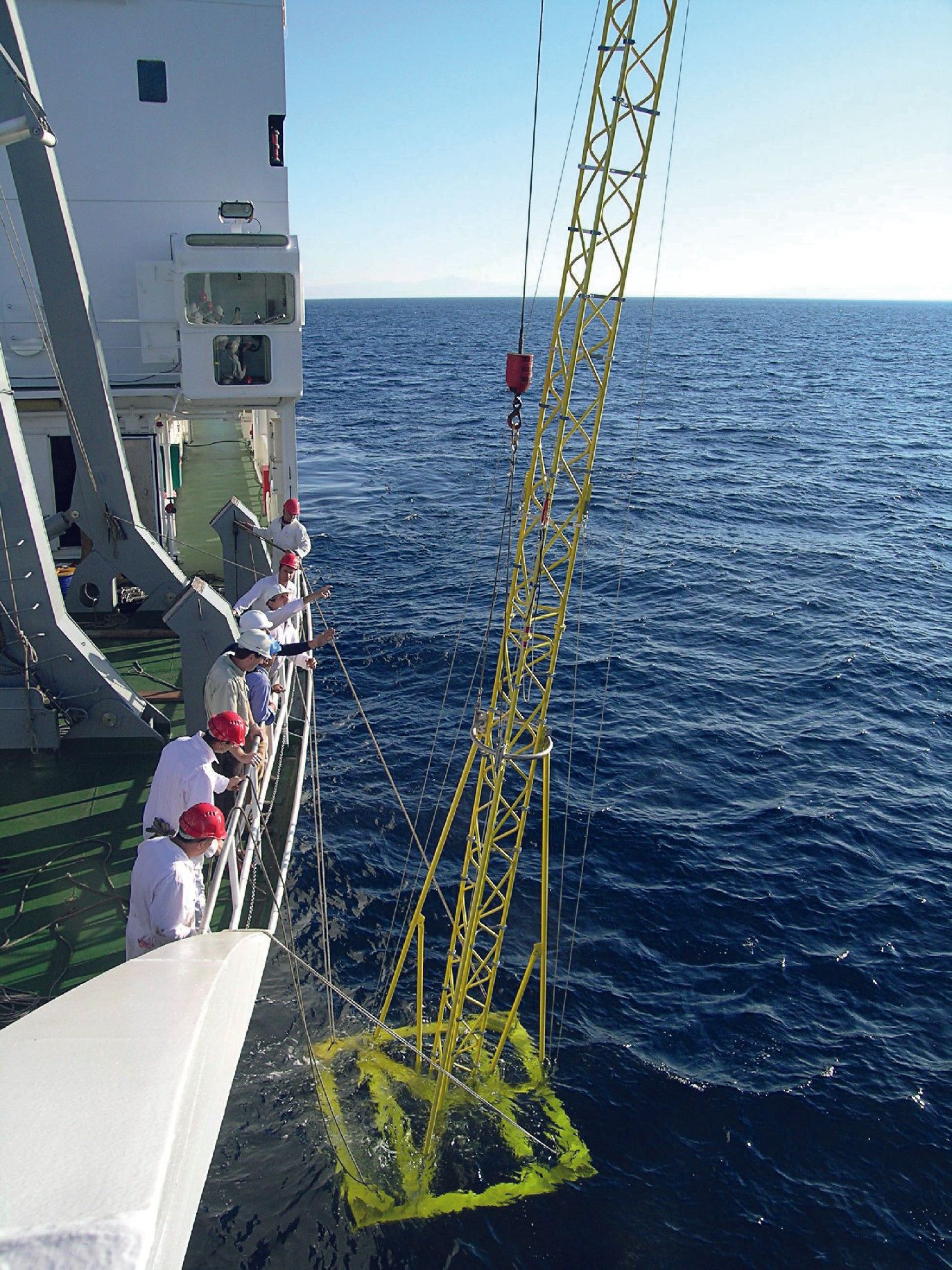

During the years, thanks to the collaboration with highly qualified clients, we have acquired specific skills in the construction of equipment and components for research and underwater activities.

Working solutions that conform to all community, national and regional regulations all completed in a timely fashion.

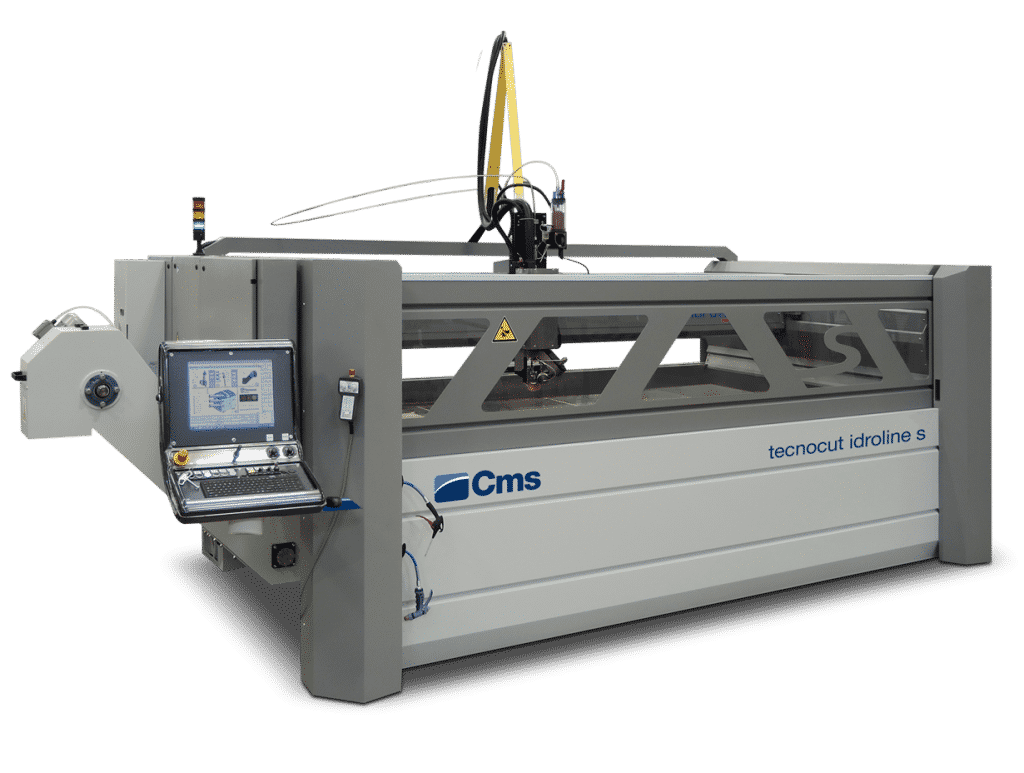

The cutting system can directly perform CAM operations, compatible with the DXF CAD format.

The system can cut a wide range of materials:

Carbon Steel, Stainless Steel, Aluminium Alloys, Titanium, Brass, Copper Alloys, Marble, Granite, Glass, Ceramics, Industrial Gaskets, Sponge, Rubber, Insulation Foams, Composites and Special Alloys.

Protected area

We have an armoured room, with a safe, where we keep all documentation etc. related to reserved projects.

"Iron Free" Zone

Area intended for stainless steel processing with particular criticalities